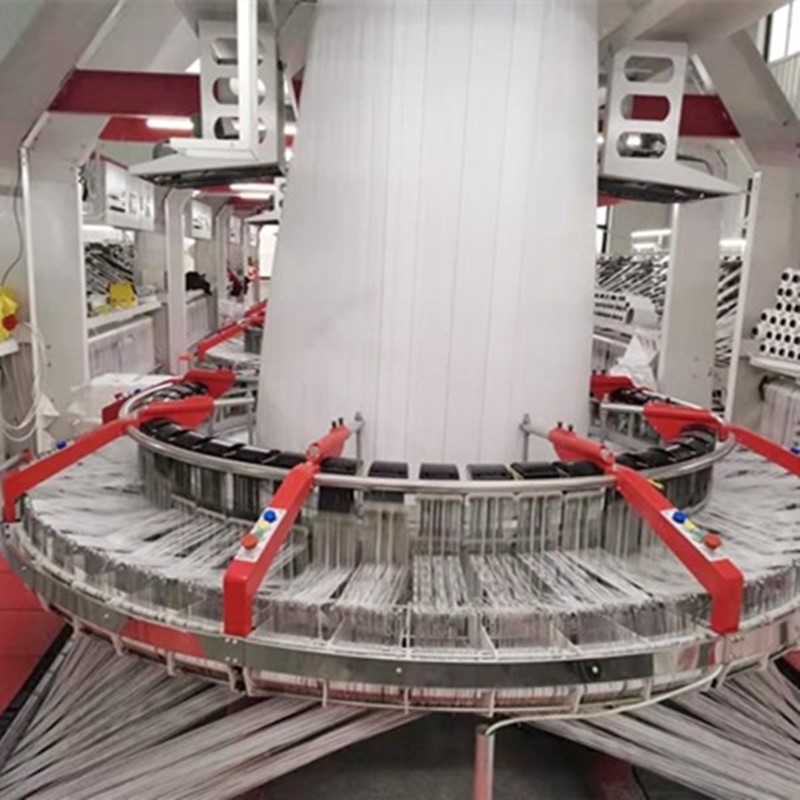

Circular Loom for Big Bag Base Cloth

Machine Performance

This type circular loom is latest plane cam structure, weaving the cylinder or flat cloth with PP

and HDPE flat yarns.

• Latest plane cam structure -adopt idler wheel from shuttle, non-lubrication

• The brown belt made of high-strength and high-toughness material, with brown silk, runs smoothly and has low noise.

• Complete weft and weft automatic detection system

• Man-machine interface centralized control, easy to operate

• Automatic Tension control by using load cell

• Shuttle material: Aluminum

• Machine with button to press and operate

Each machine consists of the following

1、Main body of the circular loom(including machine frame、lifting cloth device and electrical cabinet )

2、Warps frame:two sets(spare parts,to be assembled on site)

3、Winder torque motor:one set

4、Let- off motion device:two sets(spare parts,to be assembled on site)

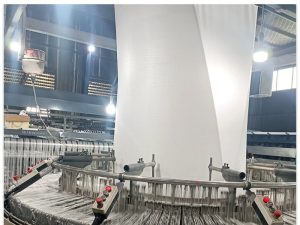

Specification

Revolution of the motor: 86r/min

Power of main motor: 5.5kw

Number of shuttles: eight

Track width: 125mm

Production width: 1000mm-1450mm

Density of wefts: 8-16piece/hour

Production speed: 68m/h-135m/h

Number of warps: 1780pieces

Max. Diameter of warp: 140mm

Max. Diameter of weft: 100mm

Let- off motion device: automatic

Warp broken control: Broken by the automatic stop

Weft broken control: generator type warp/weft stops

Tube size: as required

Winder device: two sets

Winder width: 1500mm

Max. Diameter of winder: 1200mm

Equipment dimension: (L)15.04mX(W)3.16mX(H)4.0m

Equipment weight: about 6T