China Automatic PE bottle shape liner sealing machine factory and manufacturers | VYT

Description

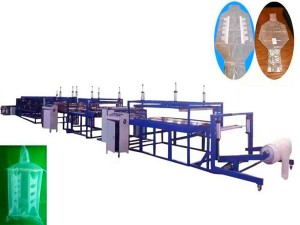

This machine is our company spent many years of research and experiment, made bottle shaped liner sealing machine. This machine has many functions, such as bottom sealing, bottom cutting, edge sealing, bottle mouth sealing and bottle mouth cutting. It is the only machine made in China at present. The size of the machine is accurate, the efficiency of a machine can replace the workload of at least 10 workers, which reduces the labor cost and improves the efficiency. It fills in the blank of this kind of special-shaped bag machine in China.

Advantage

Mitsubishi series industrial bottle shape liner sealing machine computer control system, the spindle motor is driven by the world’s advanced AC servo control technology, with the characteristics of large torque, high efficiency, stable speed and low noise.

The design of operation panel is diversified, which can meet the requirements of different customers; the system adopts Chinese structural design, which is convenient for installation and maintenance.

Parameter

| 1 | PE bag(M)width(mm) | 1200 (Max) |

| 2 | Inner bag length(mm) | 2000-8000 |

| 3 | Sealing width (mm) | 8 |

| 4 | Cutting precision(mm) | ±10mm |

| 5 | production capacity(pc/h) | 80-180 |

| 6 | temperature controller | 0-350℃ |

| 7 | Total power | 36Kw |

| 8 | Voltage | 380V(50HZ),3ph |

| 9 | compressed air | 10Kg/cm2 |

| 10 | Installation dimensions(mm) | 23500*1650*1500 |

| 11 | Machine weight(kg) | 3000kg |

| 12 | Applicable materials | LDPE,HDPE,NYLON coextrusion film |

Electrical configuration table

| Item | Name | Qty | Remark |

| 1 | Programmable controller PLCFX3GA | 1 | Mitsubishi, Japan |

| 2 | Touch screenGS2107-WTBD | 1 | Mitsubishi, Japan |

| 3 | Server | 3 | Mitsubishi, Japan |

| 5 | Servo motor 1500W | 3 | Mitsubishi, Japan |

| 6 | Frequency converter FR-E700 | 3 | Mitsubishi, Japan |

| 7 | Motor 500W | 3 | Zhongda |

| 8 | Switching mode power Supply 24V-75W | 1 | Mingwei |

| Remarks: the brand of electrical components can be customized according to the requirements of customers, and the details can be described in the contract. | |||

Random accessories

| Item | Name | Qty (pc) | Remark |

| 1 | Corner aluminum mold (bottle shape) | 4 | customized |

| 2 | Direct sealing aluminum mold (edge sealing) | 2 | |

| 3 | Horizontal hot stamping aluminum mold (back cover) | 1 | |

| 4 | Corner silicone mold (bottleneck) | 4 | |

| 5 | Direct hot silicone mold (edge sealing) | 2 | |

| 6 | Horizontal hot silicone mold (back cover) | 1 |