FIBC Aluminum Foil liner bag for big bag

Description

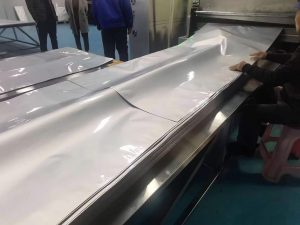

FIBC Aluminum Foil liner bag for big bag is also known as foil liners, which are made of aluminum-laminated films. Aluminum foil inliners offer superior moisture, oxygen, and UV protection, that protect the quality and integrity of the packed products. Each foil inliner can be produced using various aluminum compounds depending on the specific needs of each application. Degassing valves & valves for gas purging with Nitrogen or Argon.

Feature

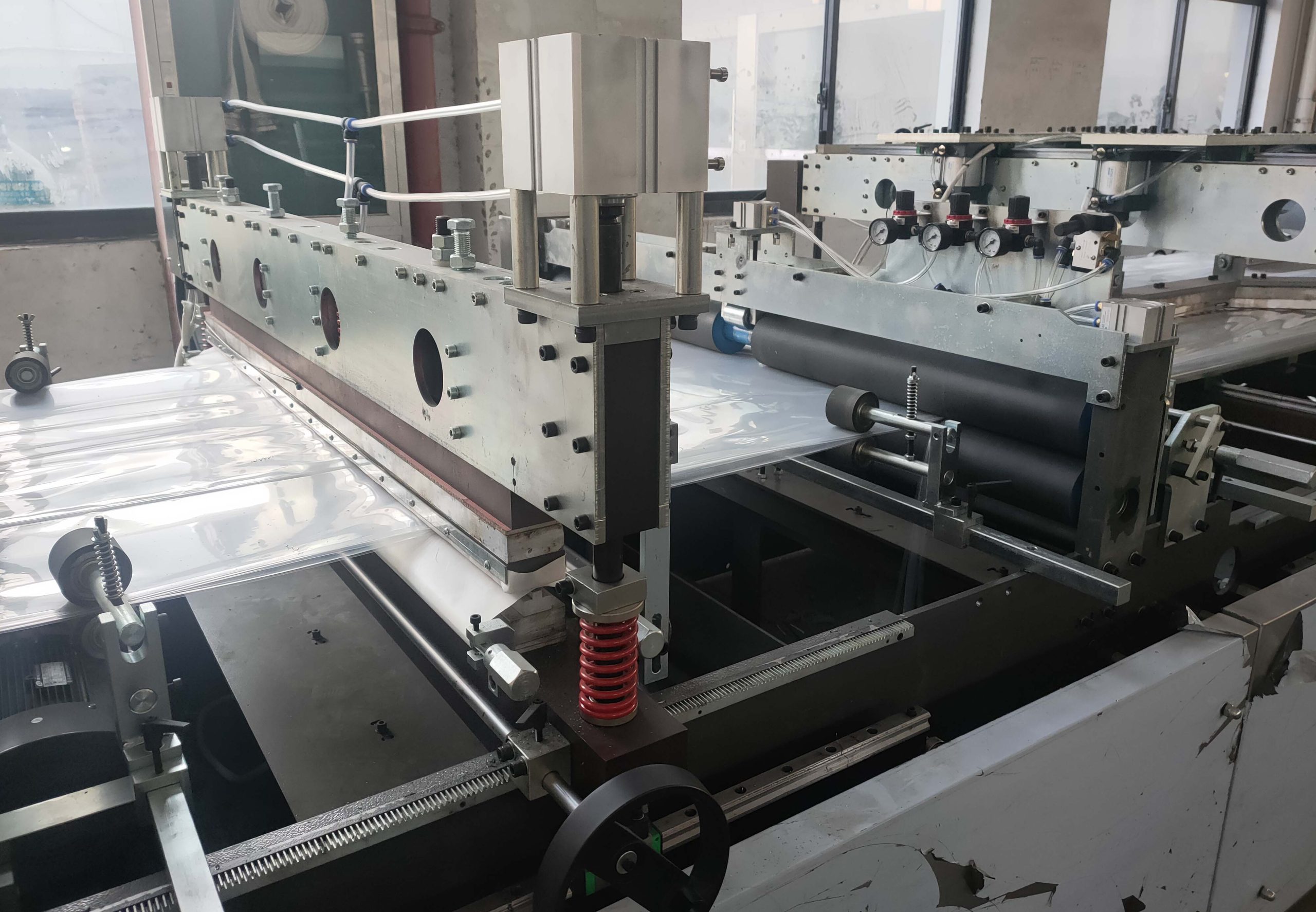

1. The machine adopt PLC system to control the cutting length with auto counting and alarming stop function.

2.Separated Unwinder stand adopts auto loading system.

3.The unwinder can automatic lift up the paper rolls by the cylinder control.Saving labors

4. Machine slitting function and equipped with trim exhausted fan to remove the slit edge of web.

5.Automatic counting fabric sheets and stop machine reaching the quantity.

6.High precision Web edge position automatic adjustment system.

7.Automatic count and stacking system.

8. Highly cutting precision with low noise that is widely apply to paper products processing industry, printing and packaging industry

Advantages

1.Intelligent controlling system, you may know the production situation at any place.

2.Save power 50% than common type

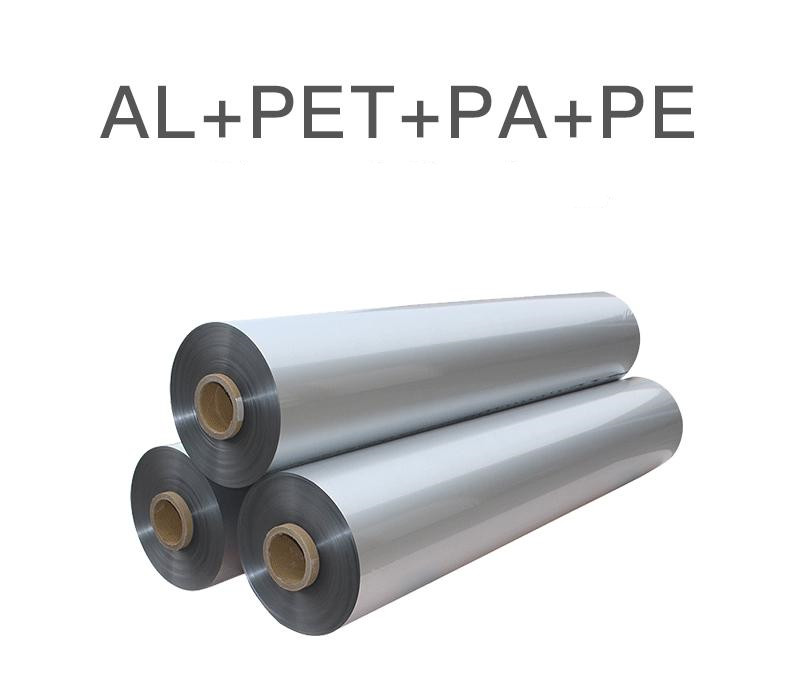

3.Suitable for all the hot sealing material,high-strength pure PE, PA co-extruded film, composite film, PLA, PBAT degradation film), breaking through the limitations of PE film, co-extruded film, new materials PLA, PBAT materials that cannot be made into bags.

Specification

| No | Model | CSJ-1300 |

| 1 | Max. cutting width | 1100mm |

| 2 | Material | composite film, aluminum film |

| 3 | Feeding speed | 16m / min |

| 4 | Cutting precision | ±0.2mm |

| 5 | Main transmission structure | coaxial eccentric |

| 6 | Main motor | 25 KW |

| 7 | Weight | 11000kgs |

| 8 | Dimension | 18000*3200*2200mm |

| 9 | voltage | three-phase 380V50Hz |