FIBC Aluminum PE Liner Bag Making Machine

FIBC Aluminum PE Liner Bag Making Machine DD-1300

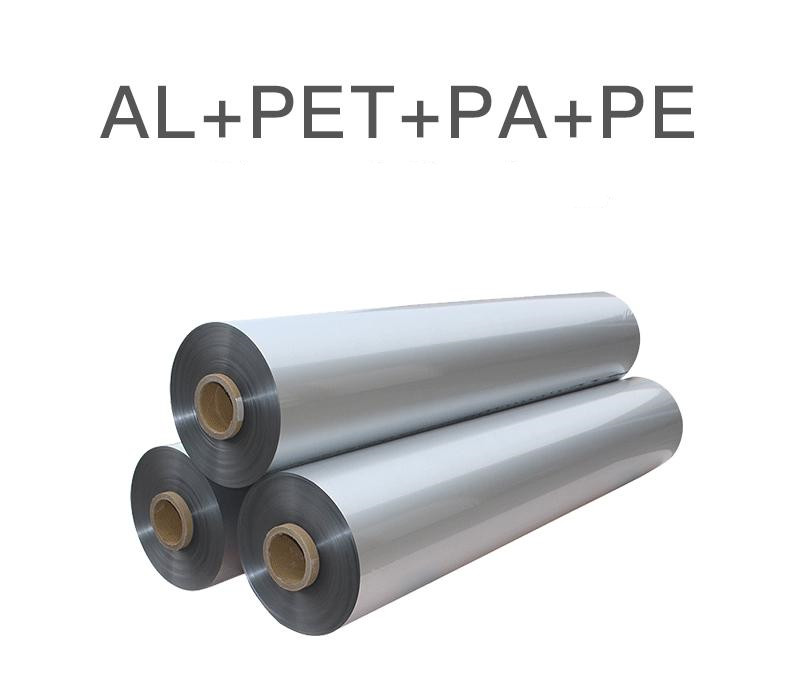

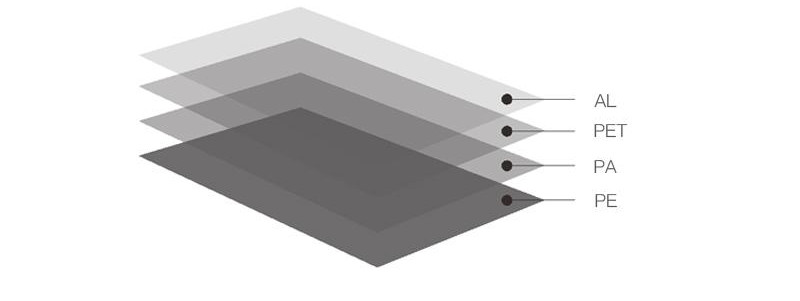

FIBC Aluminum PE liner Making Machine has high tensile strength pure PE, PA, PET and AL compound plastic material and all the other hot sealing material, the currently best-selling machines have widths of 1100mm and 1300mm.

Feature

The PLC control system of the FIBC Aluminum Liner Bag Making Machine DD-1300adopts a programmable controller as the main control unit, and dual AC servo motors as the dragging material. This system has high output torque, fast bag making speed, accurate positioning accuracy, and various parameters are displayed and operated by a 10 inch touch screen human-machine interface, which is convenient for human-machine interaction. The dragging speed and hot cutting speed are synchronously adjusted, and the operation is simple and convenient. It is currently a relatively advanced fixed length control system equipment.

Specification for FIBC Aluminum Foil Bag Sealing Machine

Specification for FIBC Aluminum Foil Bag Sealing Machine

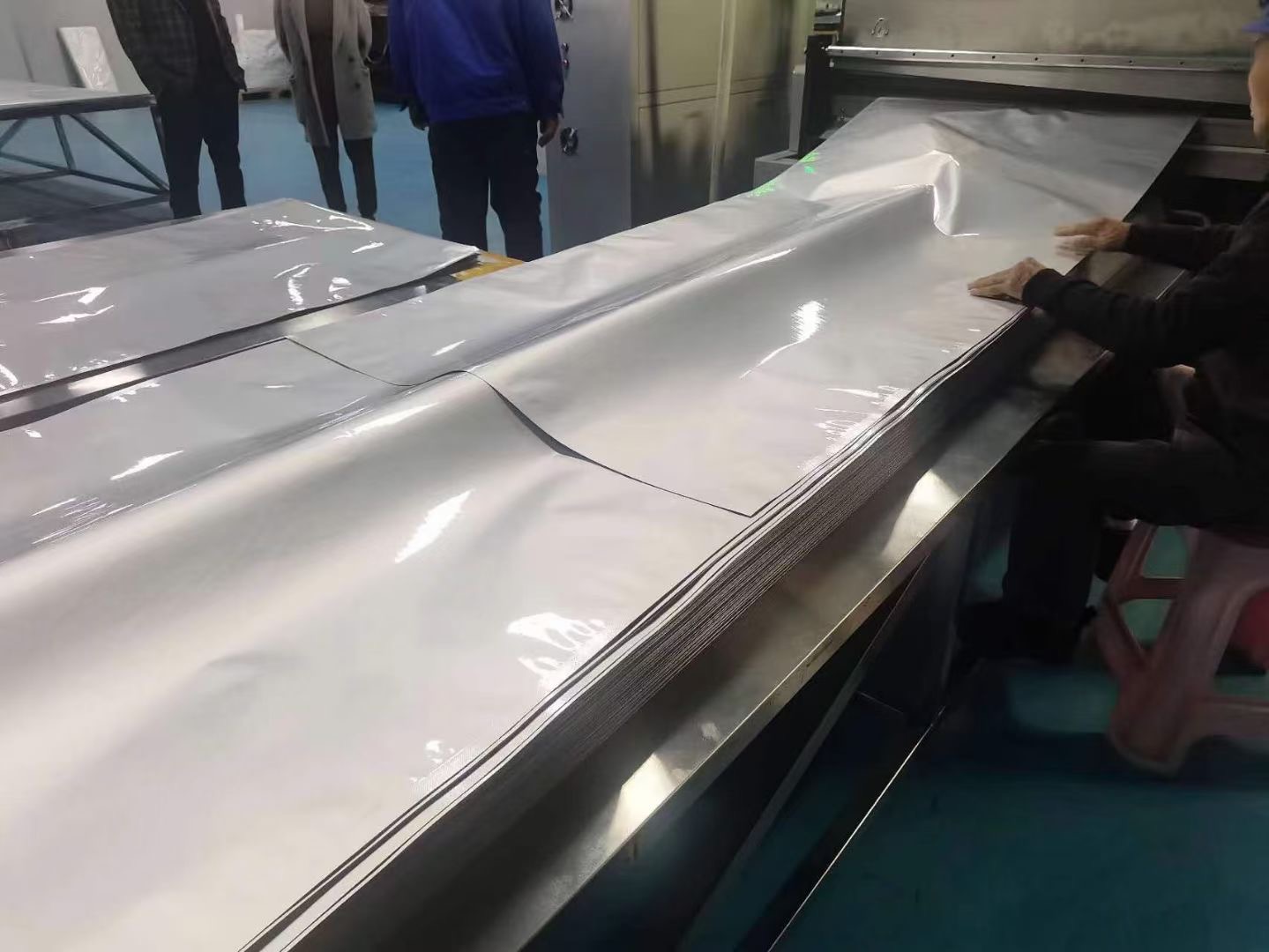

1.Bag sealing form: Triple sided sealed double bottom inserted bottle caliber bag making.

2. Equipment processing scope: composite film, aluminum film.

3. Original film width and diameter: Lmax=1300mm, Dmax=700mm, maximum bag width 1200mm.

4. Bag making length: 100-600mm, (to ensure secondary hot pressing, the maximum traction length is 600mm. If it exceeds 600mm, double feeding is used, and the maximum double feeding is 6 times feeding).

5. Bag making width: 600-1200mm.

6. Bag making speed: 10-25 segments/minute. The mechanical speed is 35 segments/minute. (The speed of bag making may be affected by the type of material and the length of cutting)

7. Feeding speed: 16 meters/minute. (Depending on the length of the bag, it may vary).

8. Main transmission structure: coaxial eccentricity.

9. Main motor: Taiwan variable frequency motor 3700W. Gear reducer i=25.

10. Traction: Front traction 2000w Panasonic AC servo, middle traction 2000w Panasonic AC servo, rear traction 2000w Panasonic AC servo.

11. Unwinding motor: CDM-CV-28-750 reducer 750w (two sets).

12. Winding motor frequency converter: two sets of 750w.

Raw material structure

We can also supply all kinds of material , this has many advantages :Oxygen barrier, Moisture barrier ,Chemical resistance ,Anti-static properties, High Strength.