China Automatic belt jumbo bag loop cut to length machine factory and manufacturers | VYT

Description

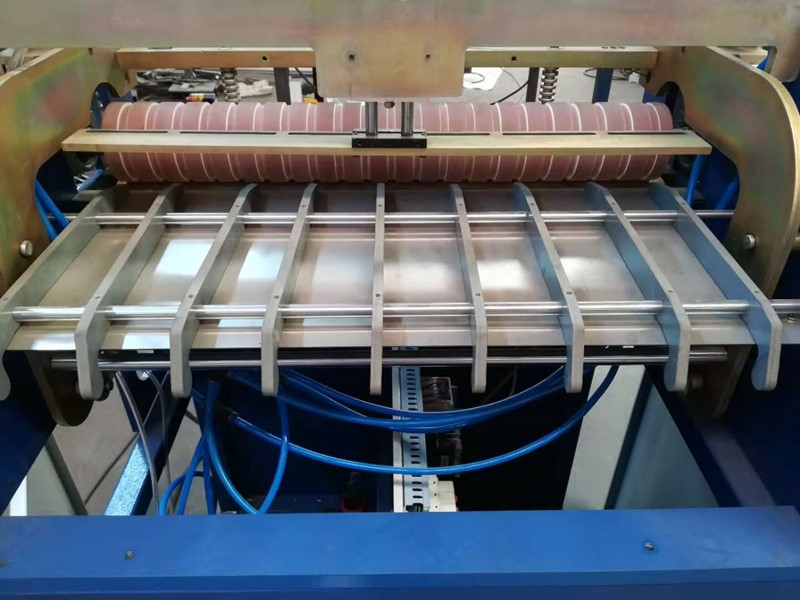

FIBC–6/8 Belt Cutting Machine is the upgraded version of FIBC–4/6 Belt Cutting Machine Cutting Machine.The frame is widened, the rubber roller and the flower roller are lengthened, and some parts are changed.

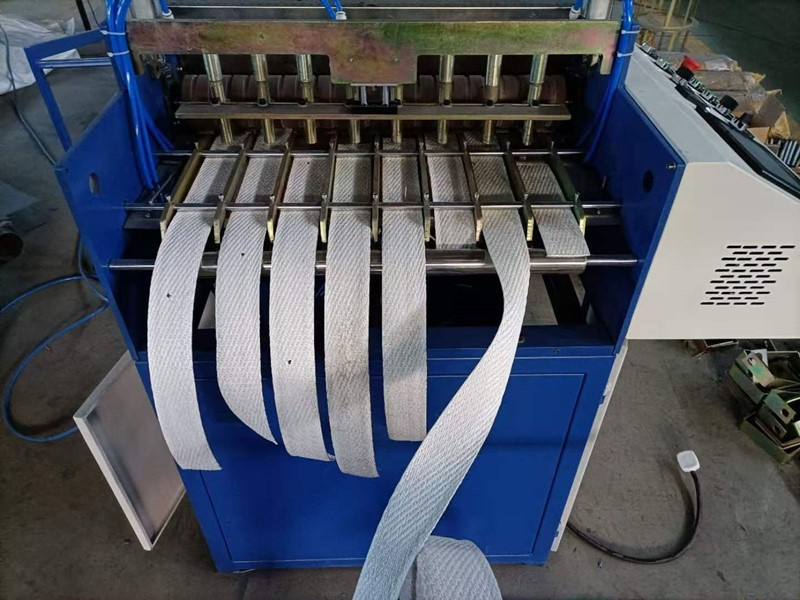

It can meet the requirements of sling width of 70mm-100 mm, 6-8 strips can be cut at the same time at one time, and the width and narrow degree can be adjusted by adjusting rod according to the bandwidth.

Feature

1. Servo fixed length control is adopted, parameter setting is directly input by human-machine interface.

2. Industrial computer (PLC) is used to control operation, pressure roller is controlled by solenoid valve and cylinder, with adjustable pressure, simple operation, less waste of the head.

3. Accurate marking and cutting.

4. High production efficiency.

Specification

| No | Item | Technical Parameter |

|

1 |

Width of feeding base fabric (mm) |

100mm(Max) |

|

2 |

Cutting length |

0-40000mm |

|

3 |

Cutting/Marking precision |

±2mm |

|

4 |

Production Capacity |

90-120Pc/min |

|

5 |

Marking Distance |

160mm(Min) |

|

6 |

Whole Power |

3Kw |

|

7 |

Voltage |

220V |

|

8 |

Compressed air |

6Kg/cm2 |

|

9 |

Temperature control |

400(Max) |

|

10 |

Whole Weight |

300kg |

|

11 |

Dimensions |

1200*1000*1500mm |

Advantage

1. VYT Loop cut could cut the set length with heat cutting automatic.

2. The powerful pneumatic upper and lower feeding guarantee the applications on different.

material have same high cutting length precision.

3. Sling width less than 7mm could cut 6 strips and 8 strips , and sling with between 10 -17mm could cut 4-8 strips at the same time.

Application

It is suitable for belt , ribbon,bandage, seal belt , parachute rope , pp band, bag belt cutting to length.

Maintenance

1. Cylinder lubrication.

If the cylinder is used for a long time, the lubricating fluid in the cylinder will be lost.

Filling method:

Locate the oil-water separator.

Close the oil-water separator and push the valve manually.

Loosen the oil cup, add proper amount of lubricant and install it back to the original place. (turbine oil 1 can be used)

Note: the water cup with drain on the left side and the oil cup on the right side.

2. The joint between the bearing and the machine is smooth.

Add proper amount of lubricant regularly.