China PE Film Auto Bottle Shape Liner Sealing Cutting Machine factory and manufacturers | VYT

Description

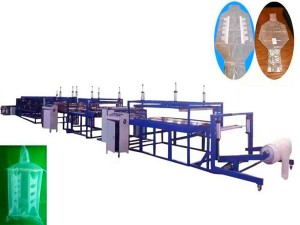

The bottle neck inner bag forming machine adopts PLC system, and the spindle motor is driven by the world's advanced AC servo control technology, which has the characteristics of large torque, high efficiency, stable speed and low noise. The design of operation panel is diversified, which can meet the requirements of different customers; the system adopts Chinese structural design, which is convenient for installation and maintenance.

Specification

| 1 | PE bag(M)width(mm) | 1200 (Max) |

| 2 | Inner bag length(mm) | 2500-3000mm |

| 3 | Cutting precision(mm) | ±10mm |

| 4 | production capacity(pc/h) | 60-120 |

| 5 | temperature controller | 0-350℃ |

| 6 | Total power | 36Kw |

| 7 | Voltage | 380V(50HZ),3ph |

| 8 | compressed air | 10Kg/cm2 |

| 9 | Installation dimensions(mm) | 2200*2100(Including electrical cabinet3100)*1800 |

| 10 | Machine weight(kg) | 3000kg |

| 11 | Applicable materials | LDPE,HDPE,NYLON coextrusion film |

Application

To protect materials inside the big bag from any environmental reasons for stopping materials to dust outside of big bag ,liner should be placed inside. Our bottle shape liner sealing machine is designed to form the liner with sealing and cutting operations, suitable for four loops big bag’s body, filling spout and discharge spout.

Working environment

Please do not use this control device in the following environment:

1. Where the voltage variation will exceed ± 10% of the freeze frame voltage.

2. The power supply capacity cannot be guaranteed in the place with specified capacity.

3. The room temperature is below 0 ℃ or above 35 ℃.

4. Outdoor or the place where sunlight will directly shine.

5. A place next to a heater (electric heater).

6. Places with relative humidity below 45% or more than 85% and places with dew.

7. Corrosive or dusty places.

8. Places prone to gas explosion or oil explosion.

9. If the place where the bottle neck bag forming machine is placed is prone to excessive vibration, place the control box in another place.

Installation

1. Control box:

Please follow the instructions to install it correctly. Before the control box is connected to the power supply, please check whether the voltage of the power supply to be connected is the same as the voltage marked on the control box, and the power supply can only be supplied after confirming the position. If there is a power transformer, the same to check before power supply. At this time, the button type power switch on the bottle neck inner bag forming machine must be placed on [off].

2. Power cord:

Please do not press the power cord with gravity or twist it excessively. Please do not put the power cord close to the rotating part, at least 25 mm away.

3. Grounding:

In order to prevent electric shock caused by noise interference and electric leakage, the grounding wire on the power line must be grounded properly. If you want to connect the electrical accessory device, please follow the position indicated.

4. Disassembly and disassembly:

To remove the control box, you must first turn off the power and unplug the power plug. When unplugging the power plug, do not just pull the power cord, you must hold the power plug by hand and pull it out. There is dangerous high voltage in the control box, so to open the control box cover, you need to turn off the power and wait for more than 5 minutes before opening the control box cover.

Maintenance, inspection and repair.

The repair and maintenance work should be carried out by trained technicians.

Please turn off the power when changing the cutter and die cutter.

Please use genuine parts.