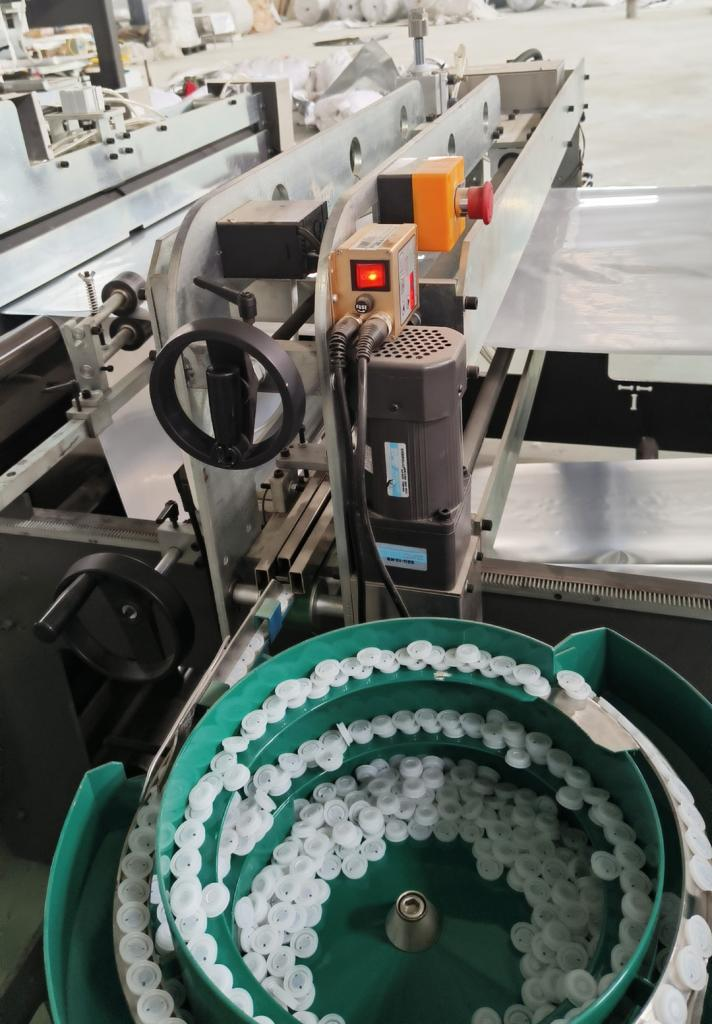

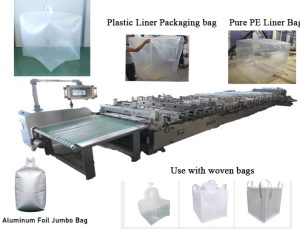

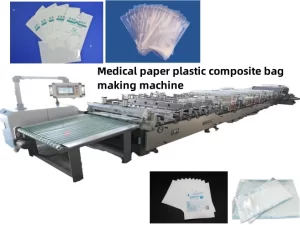

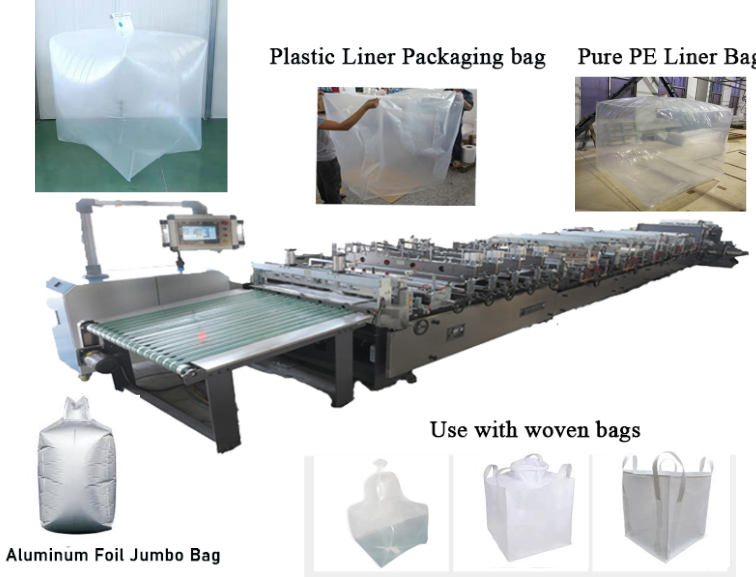

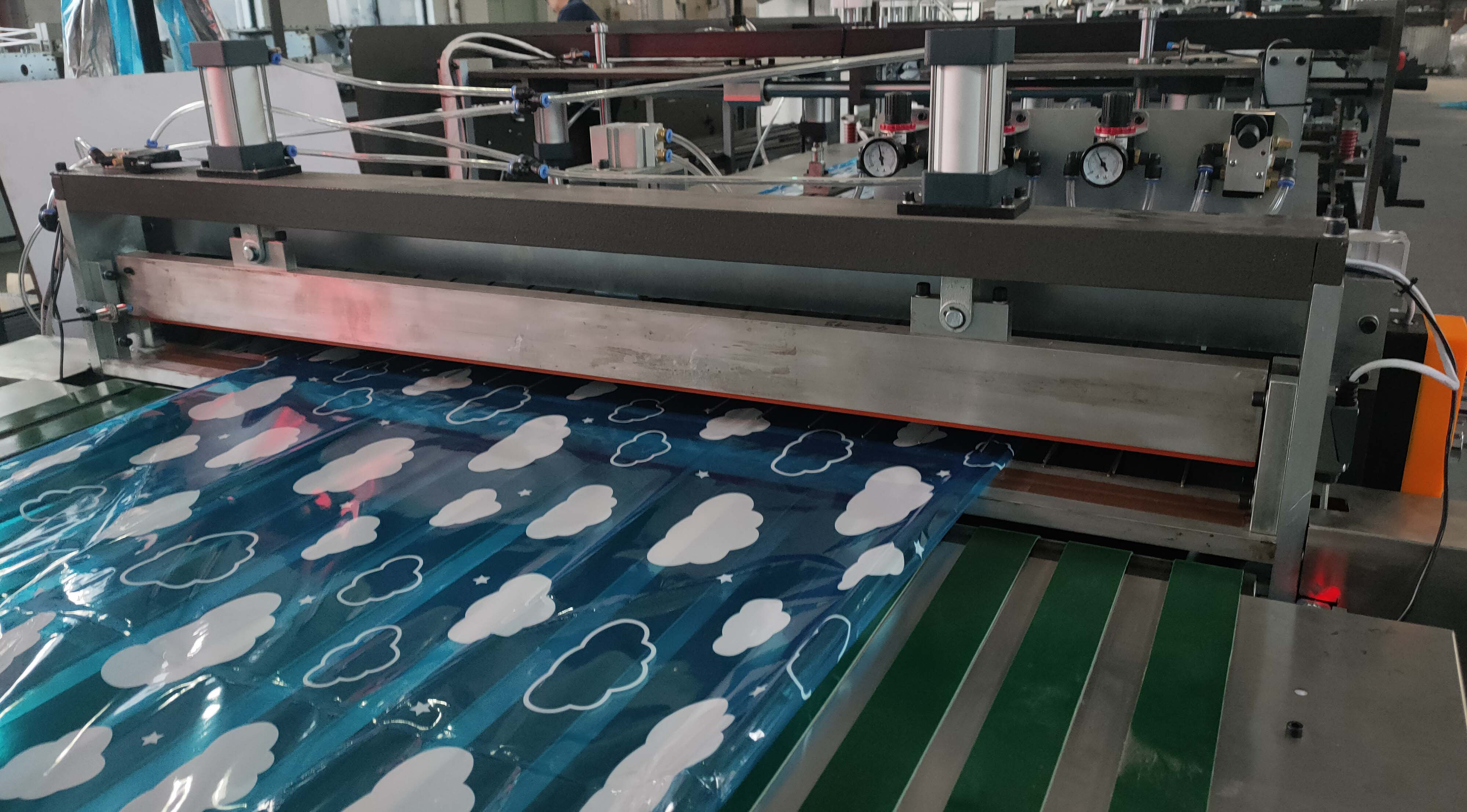

Full Automatic foldable IBC Liner Bag Making Machine

Full Automatic foldable IBC Liner Bag Making Machine can mainly produce IBC liner, and the materials can be PE film, aluminum film, and composite film. Advanced heat sealing technology can provide good sealing effects and provide an economical solution for your packaging and transportation.

IBC LINERS are mainly used with various types of ton boxes. Currently, the most widely used in the food industry is syrup packaging, which is required by major beverage factories.

to fructose syrup; in recent years, in order to alleviate increasingly severe environmental problems, the chemical industry has gradually expanded the scope of use, such as lubricants, coatings, etc.

Specification

| Production Capacity | 5-15pc/min |

| Film Roll Qty | 8PCS |

| Max Roll Dia | 1000mm |

| Max Film Width | 2520mm |

| Max Bag Width | 2500mm |

| Max Bag Length | 1600mm |

| Bag-Making Precision | ≤+/-2mm |

| Power | 15kw |

| Overall Dimension | 44000*6000*4000mm |

Feature

1.Intelligent controlling system, you may know the production situation at any place.

2.Save power 50% than common type

3.Suitable for all the hot sealing material,high-strength pure PE, PA co-extruded film, composite film, PLA, PBAT degradation film), breaking through the limitations of PE film, co-extruded film, new materials PLA, PBAT materials that cannot be made into bags.