China 28 KHz 35KHz Digital Ultrasonic Handheld Plastic Welder factory and manufacturers | VYT

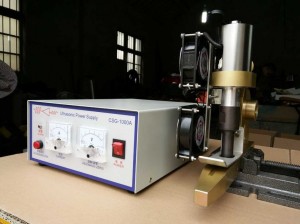

Description

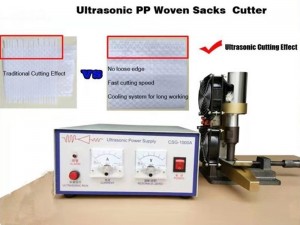

Ultrasonic welding machine for plastic remains one of the fastest techniques for welding smaller thermoplastic parts. In ultrasonic welding, one part is held stationary in a holding fixture while the other part is vibrated acoustically against it under pressure, creating frictional heat at their joining surfaces.

Speed of welding: approximately 5 seconds, depending on the material and the required results.

The ultrasonic technology ensures strong and high-quality welding between the assembled parts without using additional materials.

Specifications

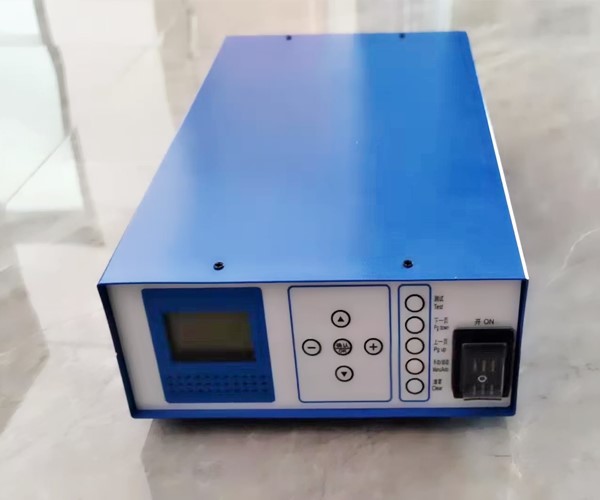

Ultrasonic generator + ultrasonic transducer+ horn.

1.Shape size: long 320mm × wide 180mm × High 90mm

2.Generator weight: 5Kg

3.Output Power: 700W

4.Output voltage: 0-3000VAC

5.Operating ambient temperature:-20 ℃ to 65 ℃

6.Sinusoidal harmonic parameter: ≤ 0.2%

7.Input power factor: ≥ 75%

8.Operating Frequency: 28KHz/35KHz/

9.Working Power supply: AC220V 50Hz/60Hz

10.Mold frequency range: ±400Hz (according to 15KHz ultrasound as an example, mold frequency in 14.40-15.20KHz can be automatic frequency tracking.)

11.Automatic tracking accuracy: 0.1Hz

12.Power repetition consistency: ≥ 97%

13.Remote terminal dynamic response time: ≥ 30ms

14.485 communication to support standard MODBUS RTU protocol

Advantages

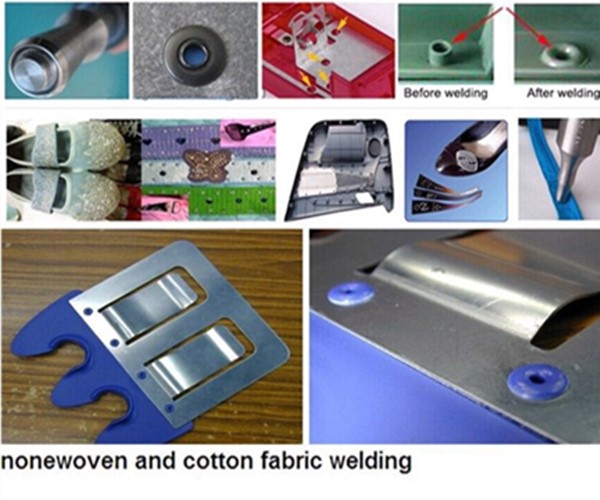

Applications

Electronic and electrical appliances, auto parts, clothing and packaging, textile industry, environmental industry, medical equipment, the toy industry, communications equipment and other industries.

Toy industry plastic toys, water guns, aquatic life video game, children dolls, plastic gifts, etc

Electronic products recording, audio tape boxes and core wheel, disk enclosure, board of mobile phone batteries and rectifier transformers, switches and sockets, remote control, electronic swatter, pseudo-imitation caps, etc

Household appliances electronic clock, electric trumpeter hairdryer, steam iron water tank, electric kettle air-hsiang, computer, etc

Stationery, daily necessities stationery, aquarium ruler, the raphe folder and shell, pen stand, cosmetics box shell, the end of the toothpaste tube seal, mirror, insulated cup, lighter, seasoning bottles sealed container

Car, motorcycle battery, front corner lamp, rear tail light, instrument, reflectors, automotive manual welding jacket, the car door welded baffle welding, automobile, car mats welding, automotive bumper repair welding

The application of the sports industry table tennis, table tennis bats, badminton rackets, tennis rackets, golf clubs, pool table, treadmill roller rope skipping handle stepper, treadmill accessories, box jumps, gymnastics mats, boxing gloves, boxing sandbag Sanda protective gear, the path to indicate the brand, the X Display Stand and other sports equipment, etc

The packaging industry

hollow crate welding, ziplock welded