China Hot New Products Automatic FIBC Fabric Cutter - Auto FIBC fabric cutting machine for jumbo bag CSJ-2400 - VYT factory and manufacturers | VYT

China Hot New Products Automatic FIBC Fabric Cutter - Auto FIBC fabric cutting machine for jumbo bag CSJ-2400 - VYT factory and manufacturers | VYT Detail:

Description

It integrates standard functions such as automatic winding, rectification, gauge length, round knife cutting, cross cutting, rounding, straight knife cutting and feeding.

Features

Automatic cloth roll up, deviation correction, length calculation, round knife incision, cross cut, circle cutting, straight knife cutting, cloth feeding and other functions are integrated (optional).

PLC control system, color man-machine interface, set data, display, record at a glance, correct, convenient operation.

Application

To automatically cut roll of woven fabric into woven fabric sheet.

Customized model

Low configuration automatic FIBC cutting machine for jumbo bag:

1. Automatic feeding;

2. Deviation device, floating device, adjusting length device (multiple deviation correction);

3. Girdle point device;

4. The effective width of cutting hot cutting is 2.4M, (the most commonly used model)

5. Automatic cloth collection function: put a tray under it, three or four hundred sheets in a stack at a time, and use forklift to fork directly to save labor cost.

Standard automatic cloth cutting machine:

1. Automatic feeding;

2. Accurate millimeter photoelectric correction;

3. Cross cutting (the common tool size is 200 mm to 650 mm);

4. Cut small round mouth (the common specification of aluminum round knife is 300 mm to 550 mm);

6. Cut the cross and mark the circle at the same time;

7. Lacing function;

8. Prevent cross cut small circle left and right position deviation device, floating device, length adjustment device (multiple deviation correction);

9. Girdle point device;

10. Cutting hot cutting effective width 2.4M, (most commonly used machine)

11. Cutting method (cold cutting), mainly for coated cloth, high efficiency, non adhesion, environmental protection;

12. Automatic cloth collection function: put a tray under it, three or four hundred sheets in a stack at a time, and use forklift to fork directly to save labor cost.

Standard automatic FIBC cutting machine:

1. Automatic feeding;

2. Accurate millimeter photoelectric correction;

3. Cross cutting (the common tool size is 200 mm to 650 mm);

4. Cut small round mouth (the common specification of aluminum round knife is 300 mm to 550 mm);

6. Cut the cross and mark the circle at the same time;

7. Lacing function;

8. Prevent cross cut small circle left and right position deviation device, floating device, length adjustment device (multiple deviation correction);

9. Girdle point device;

10. Cutting hot cutting effective width 2.4M, (most commonly used machine);

11. Cutting method (cold cutting), mainly for coated cloth, high efficiency, non adhesion, environmental protection;

12. Automatic cloth collection function: put a tray under it, three or four hundred sheets in a stack at a time, and use forklift to fork directly to save labor cost.

High standard automatic FIBC cutting and folding machine:

1. Automatic feeding;

2. Accurate millimeter photoelectric correction;

3. Cross cutting (the common tool size is 200 mm to 650 mm);

4. Cut small round mouth (the common specification of aluminum round knife is 300 mm to 550 mm);

6. Cut the cross and mark the circle at the same time;

7. 16 lacing functions;

8. Ultrasonic double folding function;

9. Prevent cross cut small circle left and right position deviation device, floating device, length adjustment device (multiple deviation correction);

10. Girdle point device;

11. Slitting (cold and hot slitting) function, (wide cloth becomes narrow cloth, remove surplus leftover material, you only need to prepare parts with common specifications)

12. The effective width of cutting hot cutting is 2.4m (the most commonly used machine), and the minimum width is 300 mm;

13. Cutting method (cold cutting), mainly for coated cloth, high efficiency, non adhesion, environmental protection;

14. Automatically take in 2 meters or less, put a tray under it, three or four hundred pieces in a stack, cut 1.3 -1.5M meters in length, 15 to 20 pieces per minute.

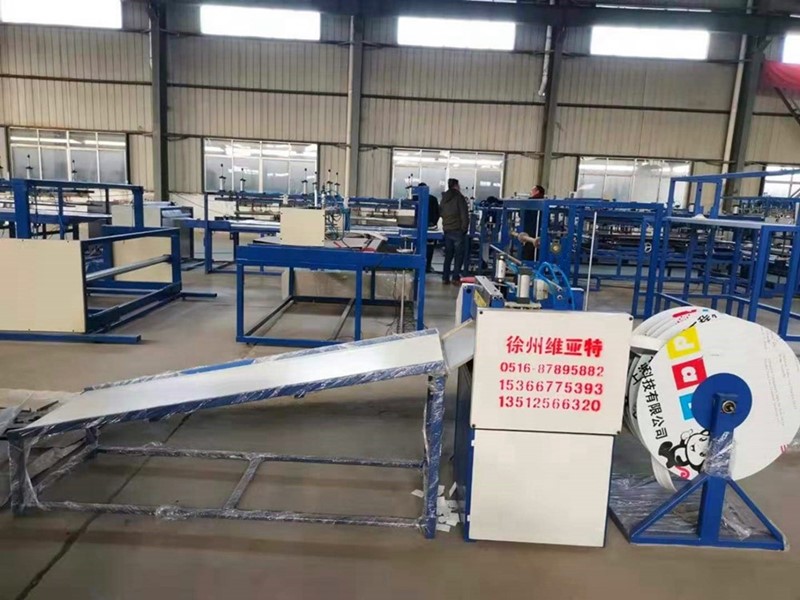

Product detail pictures:

Related Product Guide:

The really abundant projects management experiences and 1 to just one provider model make the high importance of business enterprise communication and our easy understanding of your expectations for China Hot New Products Automatic FIBC Fabric Cutter - Auto FIBC fabric cutting machine for jumbo bag CSJ-2400 - VYT factory and manufacturers | VYT , The product will supply to all over the world, such as: Canada , Johor , Zurich , Our products and solutions are sold to the Middle East, Southeast Asia, Africa, Europe, America and other regions, and are favorably appraised by clients. To benefit from our strong OEM/ODM capabilities and considerate services, be sure to contact us today. We will sincerely create and share success with all clients.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.