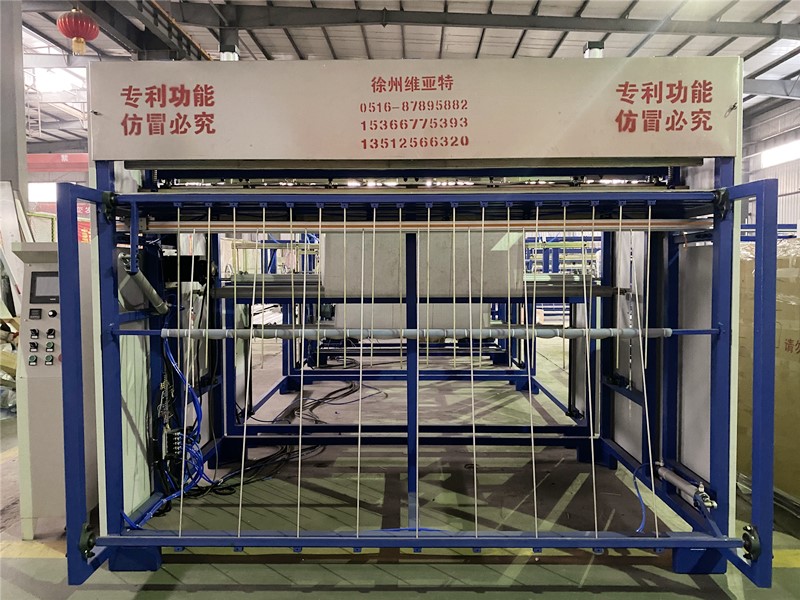

China Manufacturer for Automated FIBC Fabric Cutting Machine - Jumbo Bag FIBC Panel Spout Cutting Machine CSJ-2400 - VYT factory and manufacturers | VYT

China Manufacturer for Automated FIBC Fabric Cutting Machine - Jumbo Bag FIBC Panel Spout Cutting Machine CSJ-2400 - VYT factory and manufacturers | VYT Detail:

Description

It integrates standard functions such as automatic winding, rectification, gauge length, round knife cutting, cross cutting, rounding, straight knife cutting and feeding.

Features

Automatic cloth roll up, deviation correction, length calculation, round knife incision, cross cut, circle cutting, straight knife cutting, cloth feeding and other functions are integrated (optional).

PLC control system, color man-machine interface, set data, display, record at a glance, correct, convenient operation.

Application

Suitable for converting tubular fabrics and flat fabrics Depends on customer’s request, optional O and X punch device available for selection.

Customized model

Low configuration automatic FIBC cutting machine for jumbo bag:

1. Automatic feeding;

2. Deviation device, floating device, adjusting length device (multiple deviation correction);

3. Girdle point device;

4. The effective width of cutting hot cutting is 2.4M, (the most commonly used model)

5. Automatic cloth collection function: put a tray under it, three or four hundred sheets in a stack at a time, and use forklift to fork directly to save labor cost.

Standard automatic cloth cutting machine:

1. Automatic feeding;

2. Accurate millimeter photoelectric correction;

3. Cross cutting (the common tool size is 200 mm to 650 mm);

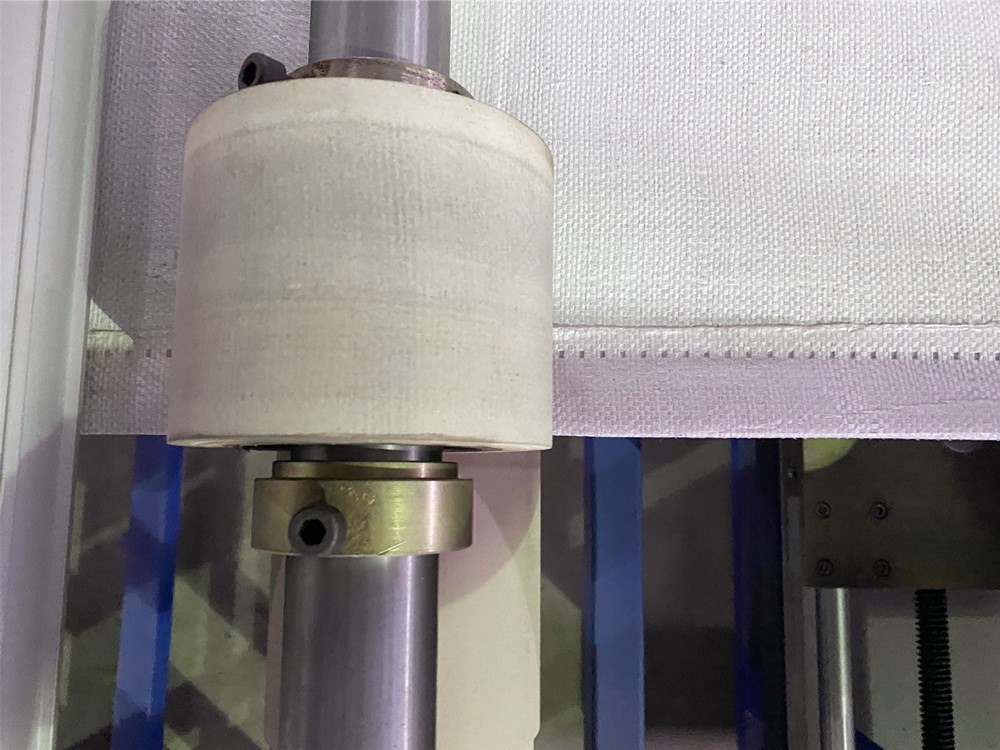

4. Cut small round mouth (the common specification of aluminum round knife is 300 mm to 550 mm);

6. Cut the cross and mark the circle at the same time;

7. Lacing function;

8. Prevent cross cut small circle left and right position deviation device, floating device, length adjustment device (multiple deviation correction);

9. Girdle point device;

10. Cutting hot cutting effective width 2.4M, (most commonly used machine)

11. Cutting method (cold cutting), mainly for coated cloth, high efficiency, non adhesion, environmental protection;

12. Automatic cloth collection function: put a tray under it, three or four hundred sheets in a stack at a time, and use forklift to fork directly to save labor cost.

Standard automatic FIBC cutting machine:

1. Automatic feeding;

2. Accurate millimeter photoelectric correction;

3. Cross cutting (the common tool size is 200 mm to 650 mm);

4. Cut small round mouth (the common specification of aluminum round knife is 300 mm to 550 mm);

6. Cut the cross and mark the circle at the same time;

7. Lacing function;

8. Prevent cross cut small circle left and right position deviation device, floating device, length adjustment device (multiple deviation correction);

9. Girdle point device;

10. Cutting hot cutting effective width 2.4M, (most commonly used machine);

11. Cutting method (cold cutting), mainly for coated cloth, high efficiency, non adhesion, environmental protection;

12. Automatic cloth collection function: put a tray under it, three or four hundred sheets in a stack at a time, and use forklift to fork directly to save labor cost.

High standard automatic FIBC cutting and folding machine:

1. Automatic feeding;

2. Accurate millimeter photoelectric correction;

3. Cross cutting (the common tool size is 200 mm to 650 mm);

4. Cut small round mouth (the common specification of aluminum round knife is 300 mm to 550 mm);

6. Cut the cross and mark the circle at the same time;

7. 16 lacing functions;

8. Ultrasonic double folding function;

9. Prevent cross cut small circle left and right position deviation device, floating device, length adjustment device (multiple deviation correction);

10. Girdle point device;

11. Slitting (cold and hot slitting) function, (wide cloth becomes narrow cloth, remove surplus leftover material, you only need to prepare parts with common specifications)

12. The effective width of cutting hot cutting is 2.4m (the most commonly used machine), and the minimum width is 300 mm;

13. Cutting method (cold cutting), mainly for coated cloth, high efficiency, non adhesion, environmental protection;

14. Automatically take in 2 meters or less, put a tray under it, three or four hundred pieces in a stack, cut 1.3 -1.5M meters in length, 15 to 20 pieces per minute.

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. Quality is our life. Customer need is our God for China Manufacturer for Automated FIBC Fabric Cutting Machine - Jumbo Bag FIBC Panel Spout Cutting Machine CSJ-2400 - VYT factory and manufacturers | VYT , The product will supply to all over the world, such as: Angola , Hamburg , Myanmar , The company attaches great importance to product quality and service quality, based on the business philosophy "good with people, genuine to whole world, your satisfaction is our pursuit". we design products, According to customer's sample and requirements, to meet the needs of the market and offer different customers with personalized service. Our company warmly welcomes friends at home and abroad to visit, to discuss cooperation and seek common development!

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!