In the evolving world of industrial packaging, the Flexible Intermediate Bulk Container (FIBC) has become a staple for transporting bulk materials efficiently and safely. Central to the production of these versatile containers is the precision cutting of spouts, an essential component that allows for controlled filling and discharging of contents. The advent of the FIBC spout-cutting machine has revolutionized this aspect of manufacturing, offering improved accuracy, efficiency, and safety. This article delves into the significance of FIBC spout-cutting machines, their benefits, and their impact on the packaging industry.

Understanding FIBC and the Role of Spouts

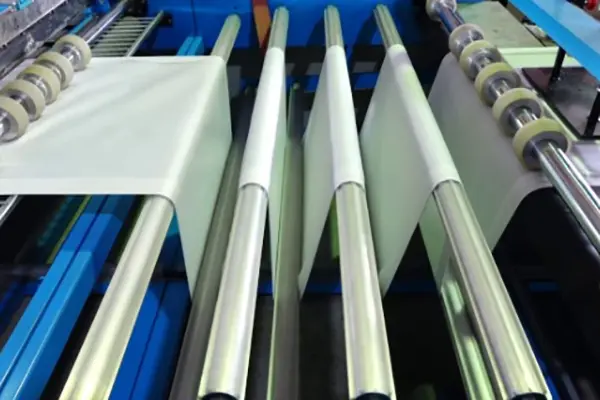

FIBCs, also known as bulk bags or big bags, are large, flexible containers typically made from woven polypropylene. They are designed to store and transport dry, flowable products such as grains, powders, granules, and other bulk materials. The spout, a crucial feature of FIBCs, facilitates the filling and discharging processes, ensuring minimal product loss and contamination.

The Need for Precision in Spout Cutting

The efficiency and safety of an FIBC largely depend on the precision with which the spout is cut and attached. Manual cutting methods, though still in use, often lead to inconsistencies and errors, compromising the integrity of the bag and the safety of the contents. This is where FIBC spout-cutting machines come into play, offering automated solutions that ensure uniformity and precision.

Features and Benefits of FIBC Spout Cutting Machines

Precision and Accuracy

FIBC spout cutting machines are designed to deliver high precision, ensuring that each cut meets exact specifications. This level of accuracy is crucial for maintaining the structural integrity of the spout and the overall functionality of the FIBC. Automated cutting mechanisms eliminate human error, resulting in consistently high-quality cuts.

Efficiency and Productivity

The automation of spout cutting significantly enhances production speed. Machines can perform cuts rapidly and with minimal downtime, allowing manufacturers to meet high demand and tight production schedules. This increased efficiency translates into higher productivity and lower operational costs.

Safety and Ergonomics

Manual cutting of spouts can pose risks to workers, including repetitive strain injuries and accidental cuts. FIBC spout cutting machines mitigate these risks by automating the cutting process, reducing the need for manual intervention. This not only enhances worker safety but also improves overall workplace ergonomics.

Versatility

Modern FIBC spout cutting machines are versatile, and capable of handling various spout designs and sizes. This flexibility allows manufacturers to cater to a wide range of customer requirements and applications, from food and pharmaceuticals to chemicals and construction materials.

Impact on the Packaging Industry

The introduction of FIBC spout cutting machines has had a profound impact on the packaging industry. By improving the precision and efficiency of spout cutting, these machines have contributed to higher standards of quality and reliability in FIBC production. This, in turn, has enhanced the reputation of FIBC manufacturers and increased the adoption of bulk bags across various industries.

Future Trends and Innovations

As technology continues to advance, we can expect further innovations in FIBC spout cutting machines. Future developments may include enhanced automation features, integration with IoT for real-time monitoring and diagnostics, and advanced cutting technologies that offer even greater precision and speed. These innovations will further streamline production processes and reinforce the importance of FIBC spout cutting machines in modern packaging solutions.

Conclusion

The FIBC spout-cutting machine has emerged as a vital tool in the packaging industry, offering unparalleled precision, efficiency, and safety in the production of bulk bags. Its ability to deliver consistent, high-quality cuts has revolutionized the way FIBCs are manufactured, ensuring that these containers meet the stringent demands of various industries. As technology continues to evolve, the role of FIBC spout-cutting machines will only become more significant, driving further advancements in packaging solutions and setting new standards for quality and efficiency.

Post time: Aug-01-2024