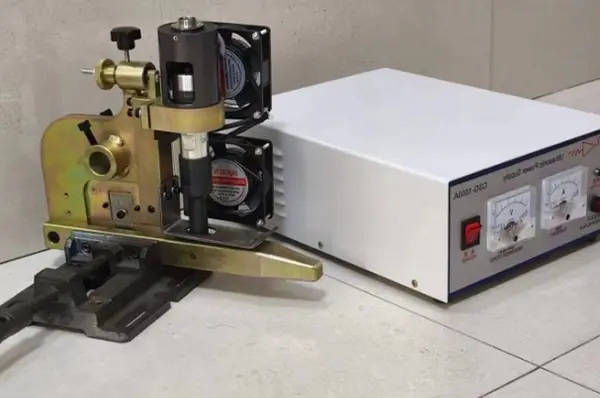

Ultrasonic fabric cutters have revolutionized the textile industry, offering numerous advantages over traditional cutting methods. These machines utilize high-frequency sound waves to cut fabric precisely and efficiently, resulting in clean, sealed edges.

Precision and Efficiency

- Clean Cuts: Unlike traditional cutting methods that can fray or damage fabric edges, ultrasonic cutters produce smooth, clean cuts without the need for additional finishing.

- Speed: Ultrasonic cutters operate at high speeds, significantly increasing production efficiency and reducing labor costs.

- Accuracy: The precision of ultrasonic cutting ensures consistent and accurate results, minimizing waste and reducing the need for rework.

Versatility

- Wide Range of Fabrics: Ultrasonic cutters can handle a variety of fabrics, from lightweight materials to heavy-duty textiles.

- Complex Shapes: These machines can cut intricate and complex shapes with ease, allowing for greater design flexibility.

- Multiple Layers: Ultrasonic cutters can cut through multiple layers of fabric simultaneously, further enhancing efficiency.

Sealed Edges

- Prevention of Fraying: The high-frequency vibrations of ultrasonic cutters melt the fabric fibers at the cut edges, creating a sealed seam that prevents fraying and unraveling.

- Improved Durability: Sealed edges enhance the fabric’s durability and extend the finished product’s lifespan.

- Reduced Finishing Costs: By eliminating the need for additional finishing processes, ultrasonic cutting reduces overall production costs.

Environmental Benefits

- Reduced Waste: The precision of ultrasonic cutting minimizes fabric waste, contributing to a more sustainable production process.

- Reduced Chemical Usage: Ultrasonic cutting does not require adhesives or other chemicals, making it a more environmentally friendly option.

Applications

Ultrasonic fabric cutters are used in a wide range of industries, including:

- Apparel: For cutting patterns, labels, and other components.

- Automotive: For cutting interior fabrics and seat covers.

- Medical: For cutting medical textiles and surgical garments.

- Industrial: For cutting filters, gaskets, and other technical textiles.

Conclusion

Ultrasonic fabric cutters offer numerous advantages over traditional cutting methods, including precision, efficiency, versatility, and environmental benefits. As technology advances, ultrasonic cutting is poised to become the standard for fabric processing in many industries.

Key benefits of ultrasonic fabric cutters:

- Precision and efficiency

- Versatility

- Sealed edges

- Environmental benefits

- Wide range of applications

By understanding the advantages of ultrasonic fabric cutters, businesses can make informed decisions about their cutting equipment and improve their overall production processes.

Post time: Sep-12-2024