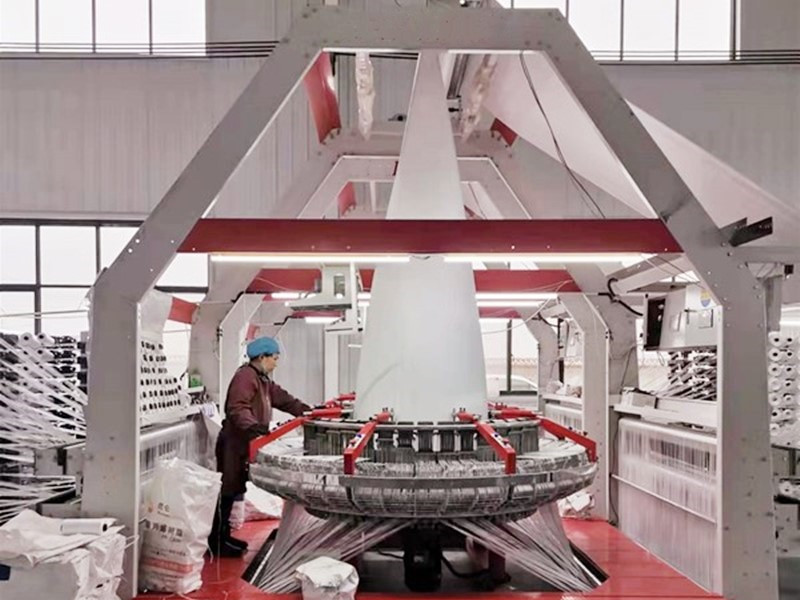

Ten shuttle circular loom for jumbo bag

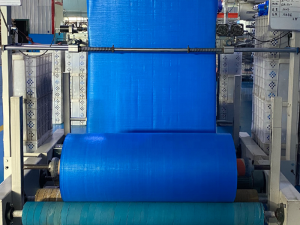

The ten shuttle circular loom is an ideal choice for weaving waterproof and sunscreen oilcloth. When there are situations such as warp breakage, weft breakage, and weft shortage, the circular loom can automatically stop working. It also has an automatic meter reading function. The eight shuttle circular loom adopts a variable frequency stepless speed control system design, with simple and convenient speed control.

Specification

| Type | CSJ-2300-10S |

| Number of shuttles | 10 |

| Main power | 5.5KW |

| Revolutions | 64r/min |

| Double flat | 1700mm-2200mm |

| Track width | 125mm |

| Weft density | 8-16pcs/inch |

| Production speed | 68m/h-120m/h |

| Number of warp yarns | 2880 |

| Warp diameter Max | 140mm |

| Weft diameter Max | 100mm |

| Winding width Max | 2300mm |

| Winding diameter Max | 1200mm |

| Machine size | (L)1540X(W)2680X(H)4720mm |

| Machine weight | 7000kg |

=

=

Equipment features:

1. This machine is controlled by five frequency converters, including variable frequency warp feeding, variable frequency winding, and variable frequency fabric lifting (controlled by dual encoders, with no loose weft when stopped and started), making the woven fabric surface of the equipment smoother.

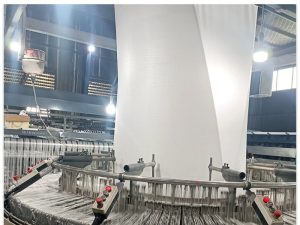

2. This machine can double split and roll, with a warp count of up to 2880 pieces, and can weave high-density, high fiber container bags and geotextiles.

3. The generator type weft yarn detector is sensitive and reliable, not affected by dust and light, safe and reliable, achieving automatic stop of broken weft and finished weft, and low defect rate.

4. The equipment has a reasonable and simple structure, high operational reliability, few vulnerable parts, convenient maintenance, and low maintenance costs.

5. Adopting variable frequency speed regulation, the machine starts smoothly and operates reliably. This machine adopts a flat cam, oil-free lubrication, and low noise.

6. Adopting variable frequency speed regulation, the machine starts smoothly and operates reliably.

7. The fabric adopts steel roller embossing and rubber extrusion extraction, and is controlled by PLC programming with an independent lifting device.